At their premises in Mielkendorf, Phi-Stone AG established a showroom that provides visitors with access to the RollFlex information material.

By introducing nano- and microstructures into organic solar cells (OPV) and organic light-emitting diodes (OLED), CAU scientists want to specifically influence the properties of the components. For this purpose, a simulation model was implemented with which the influence of grid structures on the emission characteristic of an OLED can be investigated. In a first study it was investigated both theoretically and experimentally, how the structures of the grid, absorption effects within the nanostructured OLED and the layer thickness of the cathode affect the light extraction. The results were presented in an abstract at the conference International Conference on Electromagnetics in Advanced Applications 2017 (H. Lüder, M. Bremer, M. Gerken, Simulation of nanostructured emission layers for tailoring the angular radiation pattern of OLEDs, Proceedings ICEAA 2017).

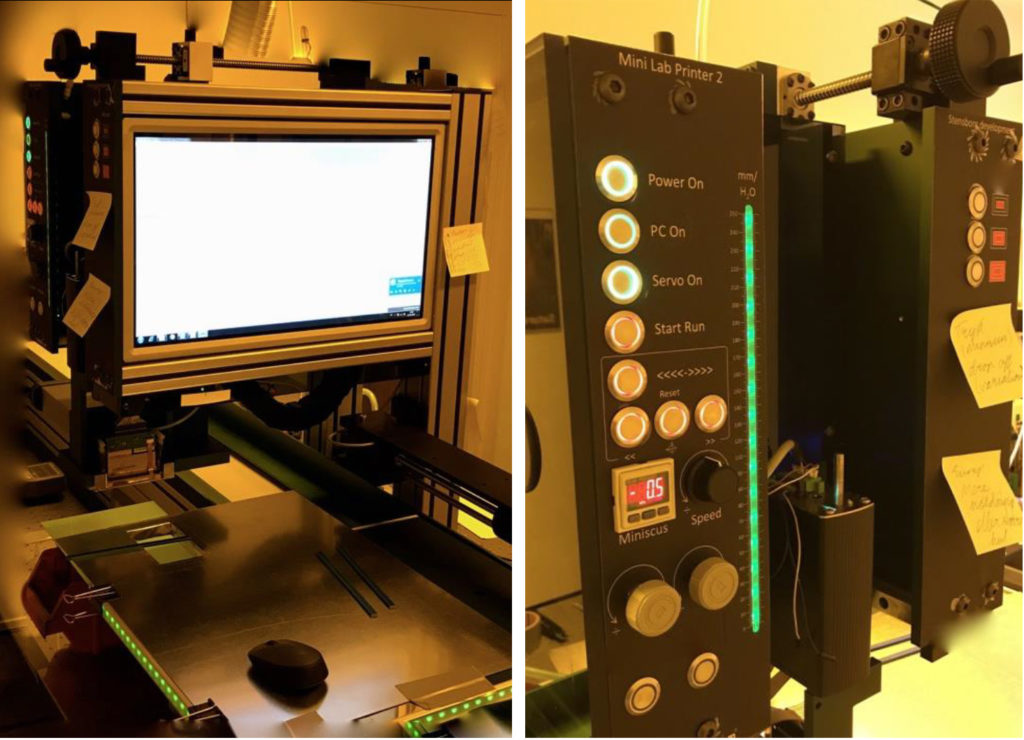

During the RollFlex project, Stensborg A / S has developed a new printing technology that makes it possible to make ultra-thin silver film coatings on different materials, such as, e.g., plastic film and glass. The thickness of these silver coatings is assumed to be about 25 nm. The process is particularly interesting for RollFlex for the R2R production of solar cells and OLEDs developed in the project because it can be used in different ways to improve the performance of the manufactured components. Thus, for example, optical diffraction gratings made with the R2R process significantly improve the light efficiency of the components due to the conformal silver coating applied in the printing process to this type of nano-surface relief structures. Similarly, with the new technology, it is possible to print circuit board tracks in different patterns. Both stages of the process are necessary for the production of solar cells and LEDs in the project.

In summary, the technology offers the following:

In the case of print of electrically conductive layers, the printer system requires only a bitmap input file. The thin silver film has a resistivity of about 7.55 · 10ˆ-8Ωm.

The technology will be implemented on the industrial NIL platform, which Stensborg A/S has developed and sells under the name HoloPrint ©

On 14 September, RollFlex opens its doors to engineers from the region to hear more about the RollFlex and the research in flexible electronics at the Mads Clausen Institute. The workshop is arranged by Elektroteknisk Gruppe and Sønderjyllands Afdeling at IDA Syd.

More information about the workshop and the registration can be found on IDA’s homepage.